A pneumatic cylinder uses the pressure of a gas to perform work, specifically linear work. The word “pneumatic” comes from the Greek and refers to air, which is the least expensive and most common type of gas used in pneumatic cylinders. Air can be easily taken in and compressed to refill pneumatic systems, and does not pose the same danger as other gases. Some inert gases may be used instead, but these must be ordered or manufactured pre-compressed in tanks and have more limited uses.

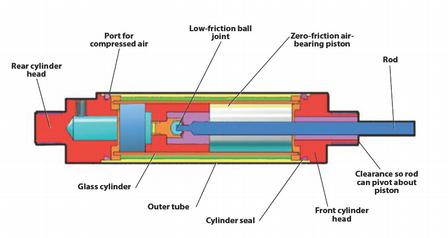

The cylinder itself contains a chamber for the compressed air to enter, a path for it to leave, a piston which does most of the work involved, and some type of action system which the piston is a part of. There are several different types of action systems for pneumatic cylinders, and each provides a slightly different kind of force. The first and most simple version is the single-acting cylinder, where a piston-oriented system forces compressed air through a solenoid valve into the back of the piston. This highly-compressed air seeks the easiest way to exit, and exerts a large amount of force on the piston face. The surface area of the piston face, or the bore size, directly affects how easily the air will manage to push the piston. The larger the bore size, the more easily the air will move it–until weight itself becomes a significant factor. As the piston is pushed out, the air exits through escape valves that are carefully position further down the cylinder. The piston falls back naturally in place until another burst of compressed air is fired into the cylinder.