Hydraulic cylinders haven’t really changed a lot over the years. The manufacturing processes are much more streamlined and the tolerances are much tighter, but for the most part cylinders are still the hard working push/pull tools they have always been. These things have literally shaped the world around us. Anything that gets lifted, pushed, hauled, dumped, dug, crushed, drilled or graded has gotten that way by some truck, crane, dozer or tractor using a hydraulic cylinder. The amazing amount of force a cylinder exerts is due to the simple mechanical principle of pressure exerted on the surface area of the piston. Simply put, the larger the diameter of the cylinder, the more it will lift.

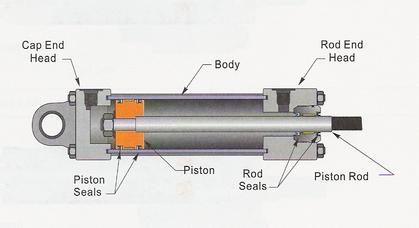

The piston is inside the cylinder, the diameter of which is known as the bore. The bore size is determined by measuring is the inside diameter of the tubing. The piston needs a piston seal to keep the pressure from bypassing to the other side, which allows it to build the required pressure (If a cylinder isn’t lifting the force it should, the piston seal is probably worn).

The piston is attached to the rod (or shaft) of the cylinder, usually with the rod passing through the piston and attached with a large nut on the opposite end. To correctly calculate the pulling force of a cylinder, the surface area of the rod must be subtracted from the formula. The rod is probably the hardest worked component in the whole system. The rod is the largest single chunk of steel in the cylinder, unpainted and exposed to all the elements. It has to be extremely strong (to resist bending), exceptionally hard (to resist corrosion and pitting), and smooth as silk (to keep the rod seals intact to prevent leakage of fluid and pressure). The stroke of the cylinder is the total travel possible from the fully retracted length and the fully extended length of the rod.

The gland or “head” of the cylinder is the part that the cylinder rod extends and retracts through. It contains the rod seals & the wiper seal which keeps contamination out of the cylinder.

The butt is the base or “cap” end. This end usually can use a variety of attachment points. There are several different ways to attach a cylinder and depending on your application you may use either a clevis, cross tube, pin eye, or tang.