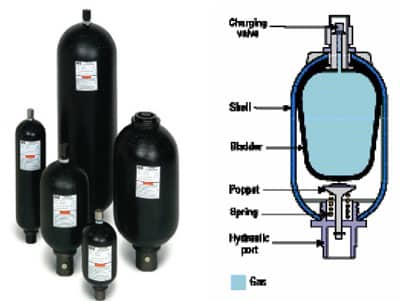

A bladder accumulator is the most commonly used hydro-pneumatic accumulator. The bladder is filled with nitrogen and fitted in a welded or forged steel pressure vessel. The bladder is made of an elastic material, e.g. rubber. The gas pre-charge pressure can be adapted via the gas inlet/outlet valve on top of the bladder accumulator.

If the bladder accumulator is mounted vertically or at an angle, the gas side must always be on top. When the pressure drops, the compressed gas in the bladder expands and pushes the stored fluid into the hydraulic circuit. At zero pressure, the bladder may be pushed out of the pressure vessel. To prevent this, a spring-loaded valve is provided on the fluid side.

The bladder accumulator is used when a high power output is required. Specially designed bladder accumulators are capable of operating at maximum pressures of up to 1,000 bar. The gas volume and effective hydraulic volume is medium, ranging from 0.5 l to 450 l.

Note that by combining several accumulators in a hydraulic sub-system, you can reach any capacity you would like by just adding extra accumulators to that sub-system.