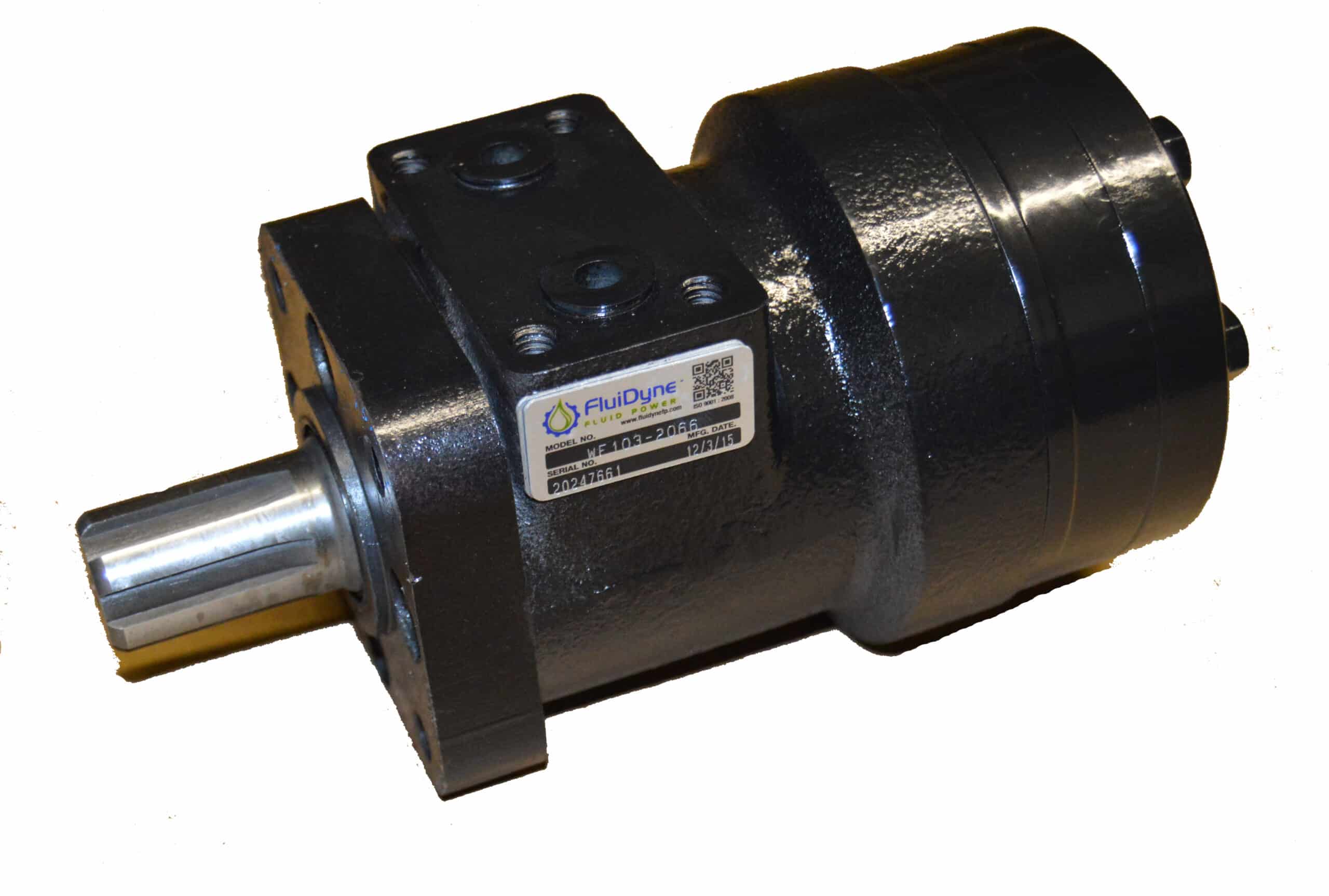

Hydraulic motors are extremely reliable, compact, and have tremendous power density. They provide a way to meet many needs for cost-effective power transmission requirements.

- Only three primary moving components are needed to transmit torque through the motor: star, drive and output shaft.

- Shaft rotation can be instantly reversed by changing inlet / outlet flow while generating equal torque in either direction.

- A variety of displacement sizes are available in each motor family that provides a wide variety of speeds and torque ranges from any series of motors.

- The results are compact, modular, economical designs that can be easily customized to suit a wide variety of application needs.

Motor options include:

- Displacement size (cubic inches or cc’s per revolution)

- Output shaft size and type

- Mounting flange type

- Porting interface

- A wide selection of special features such as integrated brakes, sensors, integrated crossover relief valves, 2-speed capability, manifold valve packages, and environmental protection suited for corrosive environments.